Joint Stock Company “E.I. Rytvin Scientific & Industrial Complex ‘Supermetal’”, in collaboration with the Moscow State University of Medicine and Dentistry (MSUMD) has been working on creation and production of noble-based alloys for prosthodontics. The main idea of the alloys’ development was to effectively combine high technological characteristics and excellent functional properties. The alloys produced by "Supermetal" have high content of precious metals (70-98%), are free from harmful alloying elements (Cd, Ni, Be, Cr, Fe), revealing high mechanical strength, corrosion resistance and biological inertness.

Created and produced by SIC "Supermetal", the products meet the best international standards in its consumer and technological characteristics. It was highly appreciated at the International exhibition in Brussels in 1995, as well as by the international community at dental symposium in Switzerland in 1998, and at the Exhibition Centre in 1998 and 2000, that confirms its competitiveness in the world market.

All the dental products were recommended by the Russian Federal Service on Surveillance for Consumer Rights (Roszdravnadzor) for use.

Product Description

PLAGODENT (Au 85%, Pt 9%, Pd 4%)

Gold-platinum alloy for ceramics

registration certificate No FSR 2010/07407

PLAGODENT is intended for producing crowns, onlays, bridges mainly with a ceramic coating, also with composite coatings or without any coating. The optimum coefficient of thermal expansion (CTE) of the alloy allows working with a wide range of ceramic mixtures. The alloy is a highly biocompatible and corrosion resistant material and do not contain Zn.

produced in marked plates of 1 g each

Primary characteristics:

| melting temperature | 1115 ºÑ |

| Vickers hardness [HV5] | 165 |

| yield strength | 250 MPa |

| elongation | 15 % |

| density | 18,1 g/cm3 |

| CTE 20-600) ºÑ×10-6 /ºÑ | 14,0 |

| color | pale yellow |

GOLHADENT (Au 75%, Ag 12%)

Gold-based alloy for the fabrication of stamped and cast dentures

registration certificate No FSR 2010/07664

GOLHADENT is a thermally strengthened wear-resistant alloy; it is multi-purpose and easy workable. It is used for the fabrication of stamped and cast dental structures (crowns, onlays, bridges, multi-surface fillings) with or without composite coatings.

produced in discs and granules

Primary characteristics:

| melting temperature | 880 ºÑ |

| Vickers hardness [HV5] | 140 |

| Vickers hardness [HV5] after heat treatment HV5 | 210 |

| yield strength | 250 MPa |

| elongation | 23 % |

| density | 15,5 g/cm3 |

| color | yellow |

PALLADENT (Pd 60%, Au 10%)

Palladium-based alloy for ceramics

registration certificate No FSR 2010/07765

PALLADENT is intended for the fabrication of cast dental structures with ceramic or composite coatings or for the fabrication of such structures in a polished form without any coating. The excellent strength characteristics and low density of the alloy allow to produce lightweight dentures. This alloy was proved to possess a high level of biocompatibility with oral cavity tissues. The alloy in question is adapted for the application of a wide range of ceramic coatings.

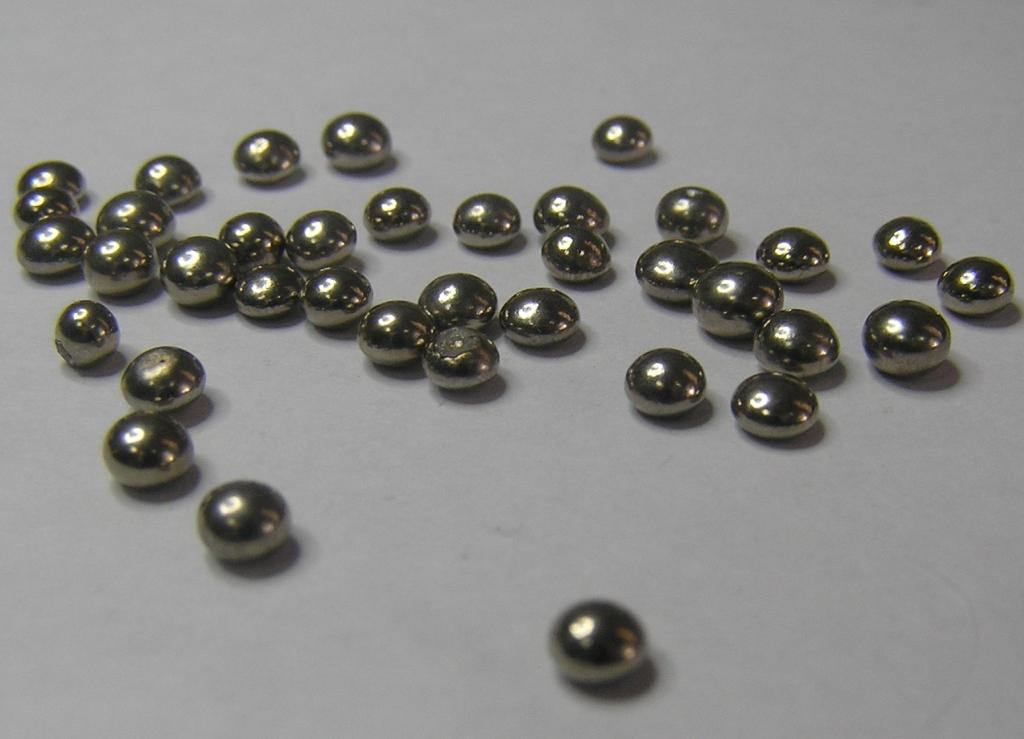

produced in granules

Primary characteristics:

| melting temperature | 1105 ºÑ |

| Vickers hardness [HV5] | 355 |

| yield strength | 745 MPa |

| elongation | 2 % |

| density | 10,5 g/cm3 |

| CTE (20-600) ºÑ×10-6 /ºÑ | 14,1 |

| color | white |

KASDENT–B (Au 72%, Pt 5%, Ag 11%)

Gold-based alloy for the fabrication of partially removable dentures

registration certificate No FSR 2012/13316

KASDENT–B is intended for the fabrication of partially removable dentures with a clammer or locking fixation. This alloy is a highly biocompatible and corrosion resistant material. The partly removable dentures made from KASDENT–B alloy have the necessary rigidity, minor wearability and do not deform in the area of clammers. This alloy can be easily polished mechanically.

produced in granules

Primary characteristics:

| melting temperature | 960 ºÑ |

| Vickers hardness [HV5] | 160 |

| yield strength | 300 MPa |

| elongation | 10 % |

| density | 15,5 g/cm3 |

| color | yellow |

KEMADENT (Au 98.5%, ZrO2 0.5%)

Composite Gold-based material for the electrochemical coating of dentures

registration certificate No FSR 2012/13899

The set of KEMADENT solutions is intended for the electrochemical golden coating of dentures (partially removable dentures, crowns, onlays) made of base alloys, in order to provide their biological inertness and corrosion resistance in oral cavity conditions. The coating obtained has high wear resistance (1.5-2 times higher than that of common golden coatings). The coating in question is applied on a finished denture. The coating process doesn’t have any harmful effects on both ceramic and composite coatings.

produced in a set of 4 solutions of 1 l each

Primary characteristics:

| Gold content in a coating | 98,5+0,5 % |

| Coating thickness | over 10 µm |

| color | from orange-yellow to yellow |

|

|

|

|

© 2026 SUPERMETAL |

||